How to Identify the Quality of Meltblown Cloth?

By Scott Chin • 06/3 @ 7:52 • How to Identify the Quality of Meltblown Cloth?已关闭评论

Melt-blown cloth is a melt-blown nonwoven cloth formed by drafting the polymer melt trickle extruded from the die spinneret orifice with high-speed hot air flow, thereby forming superfine fibers and collecting the superfine fibers on a screen or roller, and bonding the superfine fibers by itself at the same time. The melt-blown cloth mainly uses polypropylene as the main raw material, and the fiber diameter can reach 1-5 microns, thus achieving the particle blocking effect. How should foreign importers carry out meltblown fabric quality inspection in the face of meltblown fabrics produced by Chinese factories?

To carry out meltblown fabric quality inspection, first understand the main production process of melt blown cloth: melt preparation, filtration, metering, melt extrusion from spinneret orifice, melt trickle drafting and cooling, and web forming. Meltblown Booker Weight: 18g-500g, Wide Width: 160cm and 180cm in general (can also be determined according to customer requirements)

Meltblown cloth has many voids, fluffy structure and good wrinkle resistance. Ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thus making meltblown cloth have good filterability, shielding, thermal insulation and oil absorption. Can be used in the fields of air, liquid filtering materials, isolation materials, absorbing materials, mask materials, thermal insulation materials, oil absorbing materials, wiping cloths and the like.

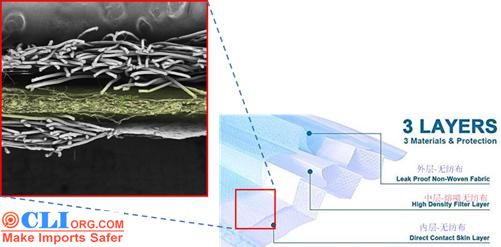

Meltblown cloth is the core material of masks. Medical surgical masks and N95 masks are composed of spunbond layer, meltblown layer and spunbond layer, wherein both spunbond layer and meltblown layer are composed of polypropylene PP material. Therefore, whether to carry out meltblown fabric quality inspection is very important to judge whether the mask is qualified.

Since the protective mask needs to have at least three layers, both sides are spunbonded nonwoven fabrics, and the melt-blown nonwoven fabrics (that is, melt-blown fabrics) satisfying the weight in the middle. We can easily judge the quality of the two outer layers of the China inferior mask by the appearance, but the quality of the meltblown cloth in the middle is difficult to judge by the appearance of the mask.

Generally speaking, in the absence of experimental equipment, the inspection company will conduct a simple inspection on the quality of meltblown cloth through the gram weight of meltblown cloth. Good meltblown cloth looks white instead of transparent due to enough gram weight, and is obviously different from spunbonded nonwoven fabrics on both sides. If the middle layer looks the same as both sides (uncommon), it is not meltblown cloth. If it looks different but obviously thin, it is meltblown cloth with small gram weight. The thinner the meltblown cloth, the worse the effect. This is the difference between medical (nursing) masks and surgical masks. It is also a medical (nursing) mask with different thickness.

Meltblown cloth is a kind of non-woven cloth, which is also called non-woven cloth, so what other methods besides measuring gram weight can be used for meltblown fabric quality inspection?

The above are just some simple testing methods for meltblown fabric quality inspection. Whether the meltblown cloth really meets the requirements for the use of masks, or whether it needs professional testing instruments to identify.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.