You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection!

By Scott Chin • 04/13 @ 9:08 • You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection!已关闭评论

You can’t imagine that a big brand like KAPPA will find serious batch problems during inspection!

This is a KAPPA single shoulder bag with a large quantity. It is divided for bag inspection in quanzhou several times before and after. The most important thing for bag products is the place of load. If there is a problem with the load, it will directly affect the service life. For the first time of bag inspection in Quanzhou , when the inspector made tensile test on shoulder straps, he found that nearly 5% of sampled products had broken shoulder straps after the test. Please see the following figure:

Before I knew bag inspection in Quanzhou, I might have simply thought that the suture quality was not good, so thet were broken. However, after further understanding of the process of products, it is known that factories can save money not only on raw materials, but also on process. In order to make more money, the factory omitted a very important but inconspicuous step for consumers.The workers did not heat seal the webbing. If it did not pass the bag inspection in Quanzhou, this problem could easily be ignored.

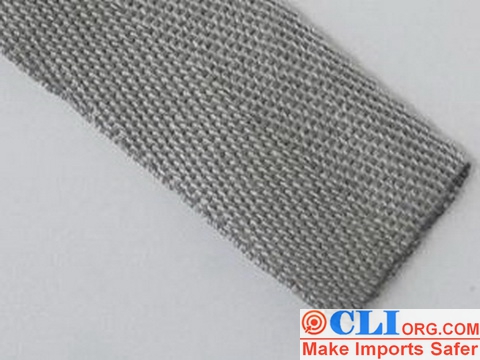

Please see the picture below. The left side is the heat-sealed webbing, while the right side is the broken part of the webbing. Heat-sealing treatment is to prevent the opening of webbing after shearing, as shown in the left figure. Without heat sealing treatment, we only need to pull the loose mouth a little, which will lead to off-line, as shown in the right picture. With such a large quantity of orders, as long as the factory omits such a small step, the profits will easily rise by several percentage!

Generally speaking, most factories have hot cutting machines, which only need to set the length in advance, put the webbing on it and heat seal the webbing while cutting automatically. However, this factory does not have a hot cutting machine, so workers need to divide the heat sealing treatment into two steps. First, the workers cut the webbing at equal length and then heat it for sealing. In order to save money, the factory directly omits the step of heating and sealing.The cut webbing is directly stitched on the product. If it weren’t for the tests made by the inspectors in the process of bag inspection in Quanzhou, this problem could not be exposed at all.The factory’s wishful thinking would have been successful. When the product is put in the store for sale, the consumer may not pull the shoulder strap like the inspector, but directly buy the product home. However, in the later use, once consumers find that the shoulder strap of the product is broken so easily, the merchants will face serious complaints! It can be seen from this that the importance of supplier quality management is to control the product quality from the production line in order to avoid future troubles.

Through the above case of bag inspection in Quanzhou, remind everyone that when buying backpacks and bags, you should pull the shoulder straps or handles at the stressed positions slightly to check whether the most basic load functions of the products have been achieved. In addition, share some tips for purchasing bags:

After learning the above tips, go to the physical store to practice and buy a favorite bag!

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.