Talk about Electric Toothbrush Waterproof Inspection

By Daniel Tsui • 08/18 @ 8:20 • Talk about Electric Toothbrush Waterproof Inspection已关闭评论

As we all know, electric toothbrushes must have certain waterproof ability, and waterproof ability is also an important indicator to determine their service life. According to the national standards, the electric toothbrush waterproof inspection can be divided into different grades. Generally, the waterproof performance of electric toothbrushes should meet the requirements of IP66, IP67 or even higher. Generally speaking, the higher of waterproof level, the higher of electric toothbrush cost.

Generally speaking, the grade of electric toothbrush waterproof inspection is IPX7, which is the waterproof grade of 7. Immersion for half an hour in a place with a water depth of one meter does not affect the use, which is qualified.

So how does the manufacturer carry out the electric toothbrush waterproof inspection?

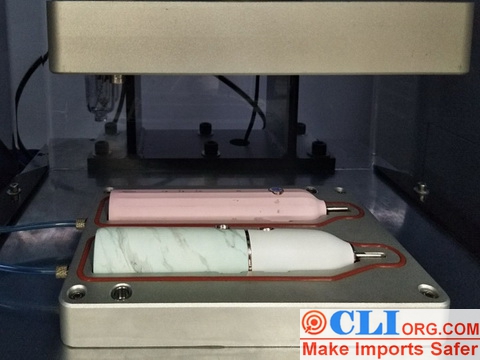

In general, it is necessary to prepare a waterproof detector. Electric toothbrushes are generally sealed integrally in order to improve waterproof performance.

When the waterproof detector is used for detection:

The electric toothbrush is fixed and sealed to form the detection end mentioned above.

Set the corresponding parameters, such as inflation time, inflation pressure, test time, test pressure and other parameters.

Put the electric toothbrush in a closed tool, start the waterproof detector for testing, find out the maximum allowable leakage value of the electric toothbrush (within the allowed range).

If there are no other problems, can carry out batch electric toothbrush waterproof air tightness test.

When the factory is unable to provide a tester on site, how does the inspector conduct the electric toothbrush waterproof inspection on the sampled products?

The above methods can effectively detect the waterproof performance of the product, but there are also many limitations, such as: unable to quantify the leakage value, subjective judgment, the need for secondary cleaning of the product, damage of unqualified parts, low efficiency, inability to determine the waterproof grade, etc. However, this on-site simulation method is still feasible as a spot check of waterproof performance.

Because electric toothbrushes often come into contact with water, if waterproof is not done well, leakage of electricity or damage will easily occur after water enters (leakage of water may cause short circuit and damage to the internal circuit board of the toothbrush). Therefore,the electric toothbrush waterproof inspection is a very important inspection step for electric toothbrush. In addition to this item, other inspection requirements for electric toothbrushes refer to the electric toothbrush inspection process.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.