Look at the N95 Mask at 100 Times Magnification. Why Can’t the Virus Pass Through?

By Scott Chin • 06/3 @ 8:11 • Look at the N95 Mask at 100 Times Magnification. Why Can’t the Virus Pass Through?已关闭评论

N95 Mask: 95% Powerful Filtering Efficiency

The N95 mask can filter most influenza viruses, dust, pollen, smog and smoke from automobile exhaust, because the filtering efficiency of N95 mask must reach at least 95%. N represents not resistant to oil,i.e. not oil-proof, and 95 represents the filtration efficiency level when 0.3 micron particles are tested.

100 times magnification to see mask meltblown fabric

During the mask inspection in the laboratory, the N95 mask will be cut open,we can see that its internal structure is mainly composed of three layers,the key layer that plays a blocking role is the high-priced meltblown fabric on the market now, which is also the key to filtering efficiency of N95 mask.

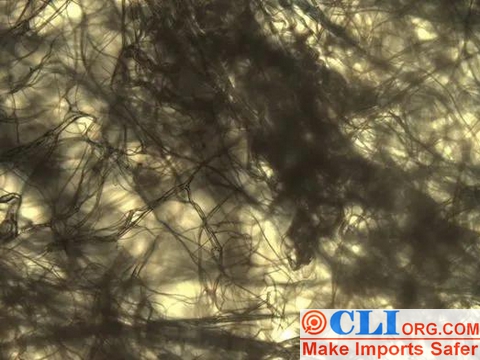

When we look at the meltblown fabric after enlarging the meltblown layer by 100 times, we can see that the meltblown fabric is made up of numerous superfine fibers crossing each other and overlapping into a dense net.

Among them, the thickness of each fiber is about 1-5 microns, and the fibers are intricate, which can prevent dust, virus and bacterial micro-foam from entering while maintaining the holes through which exhalation passes. Therefore, N95 mask meets the requirements of filtration efficiency and respiratory resistance.

If there is no comparison, there will be no harm. Then compare ordinary non-woven fabrics. Under the microscope, although the fiber looks more uniform and beautiful, the diameter of the fiber is over 20 microns and the gap is much larger. Therefore, non-woven fabrics can block bacteria and small particle dust. However, in the pre-shipment inspection, most factories do not have professional equipment. Inspectors need to identify non-woven fabrics, meltblown fabrics and the grade of meltblown fabrics through appearance to ensure that the three-layer disposable masks purchased by importers have protective effects.

N95 Mask fabric: Electrostatic Attachment (Stationary Treatment)

The meltblown layer of N95 mask is not fine enough, it is also necessary to increase the static electricity through the meltblown fabric electret discharge treatment. Within a certain range, the greater the applied voltage (the voltage of the stationary electrode), the more firm the charge is bound, thus the higher the filtering efficiency of N95 mask is.

CLI inspectors will test the electrostatic effect of meltblown fabric on site through the principle of electrostatic adsorption to judge the grade of the meltblown fabric and the quality of the mask.

Electrostatic treatment: Electret master batch

The surface charge of meltblown fabric will decay with time, and the decay time is greatly prolonged after the electret masterbatch is added. With the appropriate increase of the amount of electret masterbatch, the longer the charge retention rate is, and the decay rate is different for different electret masterbatch formulations. Electret masterbatch (2-3% is usually added) separates the positive and negative charges of polypropylene microfiber and fixes them, so that the charges can be stored for a longer time and the filtering efficiency of N95 mask can be strengthened.

Polarized fiber

There are very few Electret masterbatch manufacturers, most of which are masterbatch factories supporting meltblown fabrics, and the scale is usually small. These factories have accumulated experience in long-term production. The formula has undergone a large number of exploratory tests in terms of additives, selection of basic resin, granulation temperature, screw combination, melt finger control, additive content, etc. Combined with electrifying treatment, the indexes of filtering efficiency of N95 mask, filtration resistance, etc. have been optimized. The melt blown fabric made has also been placed for six months, one year, two years or even longer, and then the indexes of filtering efficiency of N95 mask, etc., have been tested.

Maintenance of N95 Mask-Natural Enemy of Electrostatic

With the passage of time, the binding force of the electric charge after the electret is weakened, the electric charge will wander, and the filtering efficiency of N95 mask is weakened. With the passage of time, static electricity will slowly disappear, which is why N95 masks have a shelf life, the general shelf life is about five years. The N95 mask is most afraid of water. The secret of maintenance is to stay away from water.

During the protection process of N95 mask, particles are adsorbed and static electricity is consumed. Therefore, after a period of time, a large number of particles are adsorbed, the static electricity is consumed, and there is no additional static electricity to adsorb the particles. This is also why used N95 masks cannot be reused. The principle of field testing is the same.

Finally: Because of the complexity of meltblown fibers, N95 masks and medical surgical masks can block viruses and dust! However, some criminals, in order to make huge profits, use extremely inferior, cheap and substandard raw materials, and some even directly omit the most important meltblown fabric filter layer in the middle and replace it with ordinary non-woven fabrics. Such masks have no function of filtering viruses at all, thus losing the filtering efficiency and possibly causing harm to the body. Therefore, when purchasing masks, we must pay attention to whether there is meltblown fabric in the masks.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Scott Chin

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.

SEARCH

Email Subscribers

Recent Posts

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45

- Are You Still Worried About Clothes Damaged by Hangers? 03/29 @ 8:26

Recent Comments

Monthly Files

Catalogue

Tags

BLOG

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45