By Scott Chin • 06/3 @ 6:46 • Close to see the N95 Mask Production Line已关闭评论

With the increasing number of cases of infection in COVID-19, masks have now become necessary items for people, and people’s awareness of wearing masks has been greatly “improved”. However, there are all kinds of masks on the market, and the prices are also different. How to correctly understand masks and purchase masks with protective ability has become the most concerned problem for everyone. At the same time, the inspection company has also made further matching inspections process for mask inspection.

Among the large family of masks, today we want to learn more about the N95 mask, which is one of nine particulate matter protective masks certified by NIOSH (National Institute for Occupational Safety and Health). N95 is not a specific product name, as long as it meets the N95 standard, and products that pass NIOSH review can be called N95 masks. It can filter particles with aerodynamic diameter of 0.24±0.6μm (physical diameter of 0.075µm±0.020µm) with a filtration efficiency of more than 95%.

N95 masks are produced in a strictly two-stage isolated sterile environment, and the interior (right) of the production workshop is in a first-stage sterile environment. As long as it’s a surgical mask production, it must be in a sterile environment.

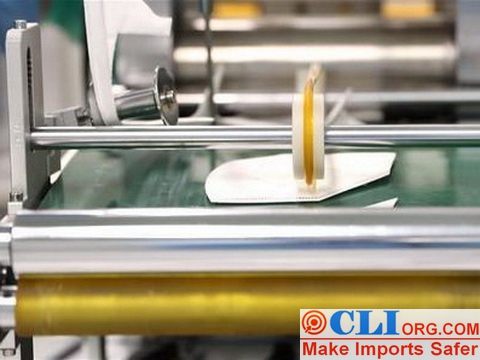

This is the N95 mask on the production line.

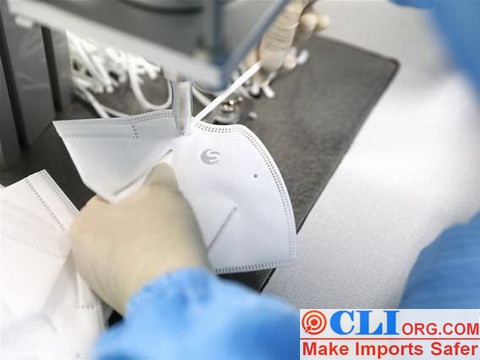

Workers are sewing earmuffs for N95 masks. During mask inspection, the headband must be elastic and firm to prevent it from falling off when worn.

Workers install mask cloth on N95 mask production line.

Workers removed the suspected unqualified mask from the N95 mask production line. The suspected unqualified mask has defects on the pressing edge and will leak air when worn. This link is the initial stage of mask inspection to avoid unnecessary workload in the later stage.

A quality inspector checks the quality of N95 masks in the workshop. The factory needs to carry out a mask inspection after the production is completed to pick out the defective products, such as the surface damage, oil stain, deformation and other defects of the mask. At the same time, the breather valve should not slip, break or deform, thus ensuring the health of consumers.

Workers are wrapping N95 masks.

Workers are packing N95 masks that have been packed in the secondary sterile area.

The protective ability of N95 mask requires laboratory assistance and physical and chemical tests, including filtration efficiency, ethylene oxide residue, inhalation resistance, exhalation resistance, formaldehyde content, pH value and other items. In the mask inspection at the scene, the inspector needs to simulate the actual use and check whether air overflows from the edge or air enters from the edge under the condition that the mask is correctly worn, with both hands covering the mask and breathing in vigorously, so as to judge the safety of the mask.

The above series of real online pictures lead us to the N95 mask and learn a simple mask inspection, so that we can protect ourselves more safely.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.