Chinese Government Remedies Meltblown Fabric Industry Chaos

By Scott Chin • 06/3 @ 7:41 • Chinese Government Remedies Meltblown Fabric Industry Chaos已关闭评论

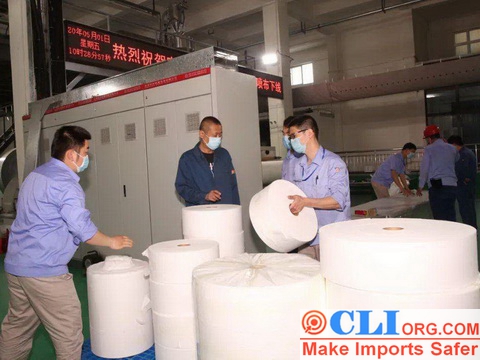

The Chinese government stepped in to control meltblown cloth chaos

On the evening of April 29, according to the documents issued by the China General Administration of Market Supervision, the Chinese government will focus on the supervision of masks and other materials, and will carry out special rectification of meltblown fabric industry in China.

Meltblown cloth is the core raw material for masks. Recently, the meltblown cloth industry has seen serious chaos, with prices soaring and plummeting, from RMB18,000 to RMB700,000, up nearly 40 times. In the recent part meltblown cloth prices fall, down to about RMB300,000. Recently, there have been reactions from people in the industry, only the price of meltblown cloth of average quality has dropped, and the price of meltblown cloth above grade 90 is still around RMB600,000. Some illegal operators took the opportunity to hoard and drive up prices, seriously disrupting the market order of epidemic prevention materials and causing chaos in the market of meltblown fabric industry in China.

For such industry problems, China’s multi-departments will jointly deploy to carry out special rectification actions on product quality and market order of epidemic prevention materials nationwide. It is required to highlight all kinds of treatment, with emphasis on strengthening supervision of epidemic prevention materials such as masks, protective clothing, respirators, infrared thermometers (forehead temperature guns) and other important raw and auxiliary materials, especially meltblown fabric industry. At the same time, highlight the whole process of rectification, throughout the epidemic prevention materials production, circulation and consumption of the whole chain; Highlight all-round rectification, coordinate domestic and international markets, and ensure the quality and safety of imported and exported epidemic prevention materials.

Focus on strengthening comprehensive rectification,aiming at the outstanding problems in the production, product quality, standard certification, inspection and testing, and market order of epidemic prevention material enterprises, administrative law enforcement, credit punishment, joint law enforcement and other means will be comprehensively used to improve the rectification effect. The specific tasks require “six comprehensives”: a comprehensive investigation of production enterprises and a good market access; To strengthen the quality inspection of epidemic prevention materials in an all-round way, and to strictly control the quality of products; Comprehensive inspection of export epidemic prevention materials, standardize the export order; Fully standardize the certification, inspection and testing activities and standardize the industry order; We will comprehensively investigate and deal with all kinds of illegal acts and severely punish them according to law. We will comprehensively improve the main level of service market,protect the legitimate rights and interests of enterprises.

General Administration Exposure: Meltblown Cloth Increases from RMB45,000 to RMB550,000

On April 26, at a press conference of the State Council, China’s market inspector made it clear that the General Administration had organized a special investigation into the act of driving up the price of meltblown cloth and disrupting the meltblown cloth industry in China. On March 11, the Ministry of Public Security deployed a special campaign to crack down on the reselling of meltblown cloth. Several non-woven fabric enterprises of the General Administration of Market Supervision conducted inspections on the sale of meltblown cloth. The General Administration of Market Supervision also exposed a number of cases of illegal price of meltblown cloth. In addition to driving up prices, a large number of unlicensed, out-of-scope and non-standard meltblown cloth manufacturers will also be shut down.

On April 23, Jiangsu Province Market Supervision Bureau of China announced that it would investigate and deal with melt-blown cloth manufacturers that operate without a license and beyond the scope of their business, especially “Forgery workshops” and “family workshops” that follow the trend of changing production, are not closely related to the melt-blown cloth industry, do not have skilled workers, and do not have the corresponding production conditions. In addition, large sales of Non-License and Non-standard and Non-Brand production operators are also under investigation.

As the demand for masks increases, meltblown cloth is still in short supply.

The international epidemic has been going on for nearly four months. While the problem of meltblown fabric industry in China is frequent, the demand is also increasing. On April 26, at a press conference of the State Council of China, Li Xinggan, Director of the Foreign Trade Department of the Ministry of Commerce, said that customs statistics showed that China’s exports of medical materials were steadily expanding. On April 24, the quantity of Chinese mask exports reach 1.06 billion, up 3.7 times from 224 million before the announcement on March 31.

From March 1 to April 25, China customs released about 55 billion yuan major epidemic prevention materials, including 21.1 billion masks. As the export of masks increases, the demand for meltblown fabrics also increases. Earlier, several manufacturers said that the overall production capacity of meltblown fabric industry in China is in excess. However, the market is mostly devoid of products, and high-quality meltblown fabrics are in short supply and still in short supply. Many meltblown fabric manufacturer said that the company’s order for meltblown non-woven fabrics in May had been completed and the demand for the order was in short supply. On April 25, the first new production line of the 4,000-ton meltblown cloth project of polyfluoro chemical industry was successfully put into operation. Sinopec’s meltblown cloth production line is also expanding. On April 30, according to the Beijing Daily News, with the successful operation of 12 meltblown cloth production lines of Yizheng Chemical Fiber and Yanshan Petrochemical Company, Sinopec’s meltblown cloth production capacity has reached 24 tons per day and 24 million surgical masks can be delivered every day.

On April 28, Yizheng Chemical Fiber company, a subsidiary of Sinopec corp, the 8th meltblown cloth production line with an annual output of 500 tons was successfully put into production. So far, eight meltblown cloth production lines of Yizheng Chemical Fiber Phase I have been fully completed and put into operation, with a daily production of 12 tons and a cumulative production of 132.5 tons of meltblown cloth. The product quality has reached KN95 mask standard, which can increase the production of 132.5 million medical masks.It is worth noting that Sinopec issued a statement saying that its meltblown cloth is only supplied directionally and is not entrusted to other units or individuals for sale.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Scott Chin

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.

SEARCH

Email Subscribers

Recent Posts

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45

- Are You Still Worried About Clothes Damaged by Hangers? 03/29 @ 8:26

Recent Comments

Monthly Files

Catalogue

Tags

BLOG

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45