The Core Material of Mask-How to Detect Meltblown Fabric?

By Scott Chin • 06/3 @ 7:55 • The Core Material of Mask-How to Detect Meltblown Fabric?已关闭评论

Medical mask and N95 mask are composed of spunbond layer, meltblown layer and spunbond layer, where in both spunbond layer and meltblown layer are composed of polypropylene PP material. As the core material in the mask, meltblown cloth has a fiber diameter of 1-5 microns. Voids are more than surface area, so meltblown cloth has good filterability, shielding, thermal insulation and oil absorption. Therefore, meltblown fabric inspection is the key to judge whether the mask is qualified.

Meltblown cloth is the core material for mask production. in order to ensure the production of medical masks and other medical materials, the Chinese government has stepped up its efforts to pass meltblown fabric quality inspection. After a large number of medical masks without meltblown cloth or unqualified ones were investigated and dealt with, the market demand for meltblown cloth has increased. Whether there is meltblown cloth or whether there is Meltblown fabric inspection has become the key standard for the inspection of masks. Therefore, if you want to produce masks, it is better to carry out meltblown fabric inspection before buying meltblown cloth, so as not to lose more than gain if the masks produced are unqualified due to unqualified meltblown cloth.

1.Appearance quality inspection: cloth surface appearance, holes, impurities, peculiar smell, micropores, crystal spots, frit, stiff silk, unreinforced area, thin net, width deviation, color difference, joint quality.

2.Mass deviation rate per unit area, longitudinal breaking strength, transverse breaking strength, longitudinal and transverse breaking elongation, hydrostatic pressure and air permeability. Spunbonded non-woven fabrics are not easy to tear and cannot be touched by static electricity. Qualified meltblown non-woven fabrics are obviously easy to tear and can be touched by static electricity.

In the combustion test, spunbonded nonwoven and meltblown nonwoven are all polypropylene products with little difference in combustion. The materials of meltblown cloth close to white are distinguished by burning, and the spunbonded nonwoven cloth and qualified meltblown nonwoven cloth are distinguished by electrostatic effect or not.

3.Microbiological index detection: total bacterial colonies, total fungal colonies, coliform colonies and pathogenic pyogenic bacteria.

In addition, meltblown fabric inspection is also tested according to GB2626-2006, requiring meltblown fabric inspection to test the meltblown fabric filtration efficiency and respiratory resistance of meltblown cloth.

(1) Particle filtration efficiency detection:

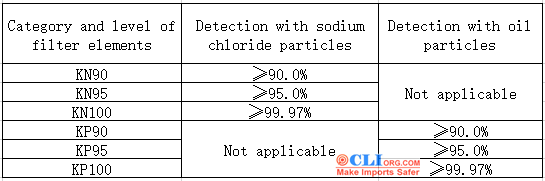

In the laboratory, sodium chloride (NaCL) particles are used to detect type N filter elements, and dioctyl phthalate or equivalent oil particles are used to detect type P filter elements.

During the testing process, the filtration efficiency of each sample shall always meet the requirements of the following table.

(2) Respiratory resistance test:

Wear comfortably. Requirements of breathing resistance to small, light weight, wearing hygiene, convenient maintenance. According to the requirements of national standards, when performing meltblown fabric inspection, the total suction resistance of each sample should not be more than 350Pa, and the total respiratory resistance should not be more than 250Pa.

This is all about meltblown fabric inspection. At present, the epidemic prevention and control situation is still grim, and the demand for mask materials is increasing. In order to effectively guarantee the product quality of masks, we must strictly guarantee the qualification of Meltblown fabric inspection, so as to ensure people’s health and protect the overall victory of the anti-epidemic prevention and control war.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.