Manufacturing Technology of Quartz Watch

By Flora Lee • 07/1 @ 1:30 • Manufacturing Technology of Quartz Watch已关闭评论

Quartz is an oxide with a composition of silicon dioxide (SiO2). Quartz is placed in an oscillating circuit, it will vibrate. Under certain conditions, it transmits its own frequency to the circuit. If this characteristic is applied to the quartz movement, the electric energy can be converted into kinetic energy through the quartz oscillator, and the circuit board can be mass-produced by mechanized equipment, and then the resistor and capacitor can be used to complete the movement. Then the case,lass and strap can be installed to become a quartz watch. After the assembled watch, for the quartz watch process inspection, every small part plays a vital role in the inspection. If any of them is not running, the product will not work properly.

Product process

Complete process: design drawings – purchase raw materials – parts processing – test – assembly – packaging

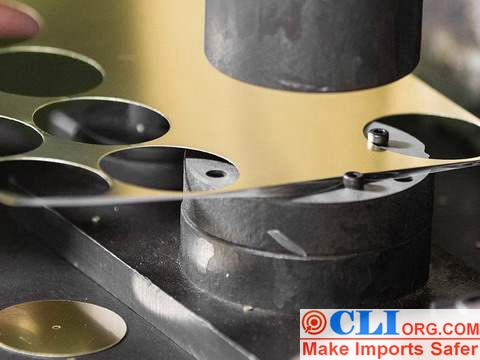

- Parts processing

The processing of various components in quartz watches requires strict quality. For example, a balance shaft that is as thin as a hair, its tolerance is only 0.005 mm. After it is qualified with a forty-fold microscope and then riveted with the balance. Such a fine operation process is normal from the perspective of each component, and in the quartz watch process inspection, the inspection and measurement of components are the key, otherwise the assembled products will have various problems.

- Component assembly

Assembling the various parts that have been processed and inspected is the final stage in the manufacture of watches. Choose to work in a constant temperature workshop while keeping the air clean and dust free. Workers must wear white coats, white hats and rubber gloves. Every part must be assembled carefully and adjusted to the best position. When a watch is assembled, it will be fully verified for ten days, including quartz watch process inspection, through the simulation, real walking seconds, test amplitude, electronic meter test, appearance and other items.

Product process impact on quality

- The influence of parts

Because the quartz watch is a crystal that uses periodic “vibration”, it gives us accurate time. It is equipped with a battery that powers an integrated circuit and a quartz resonator. Once these parts have something wrong, the function of the watch will be affected. For example, if the product is not resistant to moisture and vibration, the accuracy of time may be lost or even stopped. If the handle of the product is not installed properly, the product’s reset function may not exist when test stop function during the quartz watch process inspection.

- The impact of assembly

When assembling, if there is a waterproof mark on the product, the sealing is involved. The assembly between the case and the glass must be carried out in an environment with appropriate humidity, and attention should be paid to the accuracy of the assembly. The important point specified in the standard is Use Reliability, which is to press and push the hands to test the setting of the needle to check the accuracy of the hour,minute and the second hands.

Quartz watch production plants are generally large-scale and have complete testing equipment.If the importer requires some projects, the factory does not have the corresponding equipment, then need third-party inspection to help random Sample Picking and send the samples to Lab Testing. When this process is carried out, quartz watch process inspection has been basically completed.The remaining steps are that the factory needs to repair defective products, improves product quality control and reduces the risk of importers.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Flora Lee

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.

SEARCH

Email Subscribers

Recent Posts

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45

- Are You Still Worried About Clothes Damaged by Hangers? 03/29 @ 8:26

Recent Comments

Monthly Files

Catalogue

Tags

BLOG

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45