You Are Worth of Reading “Product Air Tightness Test”

By Daniel Tsui • 11/26 @ 1:40 • You Are Worth of Reading “Product Air Tightness Test”已关闭评论

Many of the importers’ imported daily necessities from China, and the testing items in the process of inspection naturally contain tests on whether their functions are perfect or not. For example, if you need to use a product under closed environment. you should check the air tightness or water permeability of the product and conduct tightness test. In CLI inspection, there are the following test categories:

First, for the tightness test of pipe products, inspection through water is generally adopted. All sealing nozzles of the product are manually or automatically blocked, sunk into the water and inflated by the inflator to see if there are bubbles in the pipe body in the water, if there are no bubbles, there is no leakage, and if there are bubbles, side leakage points can be seen. This is one of the simplest and most common test methods.

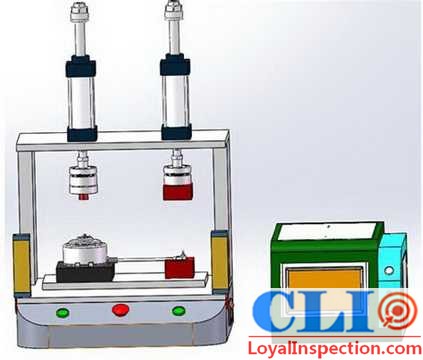

Second, mechanical products generally use airtight detectors to conduct tightness test, i.e. all sealing nozzles of the products are manually or automatically blocked, test gas enters the workpiece through the test instrument for testing, then pressure changes are judged by sensors in the instrument, and finally whether leakage occurs or not is judged. All such products will have accurate calculation formulas and data comparison, and have different standards according to the requirements of different products.

Through comparison, we can know that the water inspection method is low in cost, but it is only identified by human eyes, and there will be missed inspection. In addition, it will cause damage to some workpieces, such as rusting and corrosion of metal parts, and some workpieces will be dried after water inspection, but it is easier to detect which part of the workpiece leaks. Instrument detection cost is high, but the operation is relatively simple and efficient, especially for small workpieces. Generally, there will be no misjudgment and no damage to the workpiece. The disadvantage is that only leakage can be detected and no specific leakage can be detected. The CLI inspection will do random sampling on basis of the product characteristics, and flexible selection of the corresponding tightness test method.

Third, compare the difference between air tightness test and air pressure test. First of all, they have different purposes. The air tightness test is to check the tightness of the container, and the air pressure test is to check the pressure strength of the container. Secondly, the test pressure is different, and the air tightness test pressure is 1.15 times of the design pressure of the container.

During the actual inspection of CLI, the product’s tightness test will be performed by simulating the consumer’s living environment, such as a toilet box with a sealing ring cover. CLI will put a proper amount of water in the lunch box, cover the lid and fasten the buckle. A piece of dry white paper will be placed on the table and the lunch box will be placed side by side. After 3 – 5 hours, check whether there is any water stain on the paper and whether there is any water stain on the side of the product to check the water penetration rate of the product.

The importer’s inspection requirements for such products are to formulate different requirements and standards according to the characteristics of the products and to combine the product inspection protocal of CLI , gives a more complete inspection process.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Daniel Tsui

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.

SEARCH

Email Subscribers

Recent Posts

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45

- Are You Still Worried About Clothes Damaged by Hangers? 03/29 @ 8:26

Recent Comments

Monthly Files

Catalogue

Tags

BLOG

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45