The Production of Sanitizer Is Not Complicated

By Daniel Tsui • 12/24 @ 9:24 • The Production of Sanitizer Is Not Complicated已关闭评论

Speaking of sanitizer,everyone must be familiar with it.Because sanitizer is widely used in all walks of life and it is everywhere in life.There are many kinds of sanitizers in the market,but there is not much difference in sanitizer production process.Many people have little understanding of sanitizer production process.Firstly,according to different uses,sanitizers can be divided into high-efficiency sanitizers,medium-efficiency sanitizers and low-efficiency sanitizers.Their components generally include oxidants, alcohols, aldehydes, phenols, surfactants and so on.

All these sanitizers with different components should be treated with raw materials,stored and stirred before production.Taking the sanitizer filling line as an example.The sanitizer processed in the early stage is filled and capped.Finally labeled and packing after printing barcode,so that the sanitizer can be sold in the market.When the epidemic broke out in China,the sales of sanitizer continued to rise,resulting in a shortage of supply.A large number of businessmen aiming at business opportunities began to buy production equipment and raw materials.They worked overtime to produce sanitizer. Although China’s sanitizer production capacity has increased significantly,it also contains many illegal products,which need government departments to start to check from the source and strictly monitor.

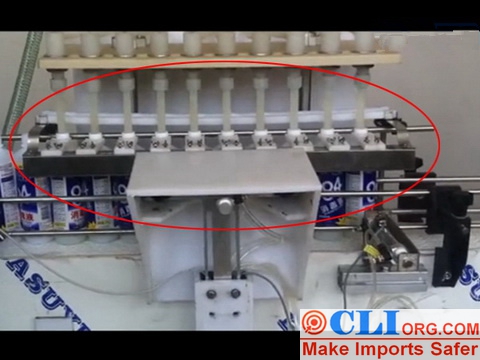

Next,we will explain the source of sanitizer production process from the specific filling equipment. The filling equipment for sanitizer production can be used on line,which is a sanitizer filling line and belongs to the anti-corrosion production line series.

First,empty bottles are sorted.The first is the rinsing process,after which the drying will begin.The dryer can choose different types of machines according to client needs.Then,the empty bottles enter the split screen spiral detection and positioning through the conveyor belt.And then enter the filling station,the filling head descends,the filling valve opens.The filling valve closes and the filling head rises to complete the filling operation in sanitizer production process.

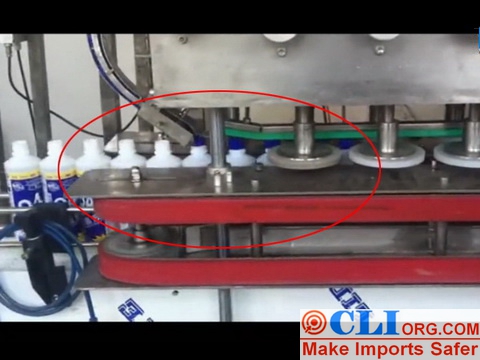

Then enter the capping and capping process,the bottles are automatically capped and then capped.

Finally,it is sealed with aluminum foil and the bottle mouth is melted by electromagnetic induction heating and then stuck to the bottle mouth to complete the filling and packaging of the entire sanitizer production process.

The factory can choose whether to label the bottle according to the client’s needs.When labeling,they can choose manual labeling or machine labeling.At present,automatic labeling machine is used for labeling in sanitizer production because of its good labeling effect and high efficiency.On the packaging of sanitizer bottle,the allocation ratio will be printed.And the use place will be marked, so as to ensure the safety of consumers.

At present,the global epidemic situation has not been well controlled,so people still have great demand for epidemic prevention products.In addition to wearing masks,it is necessary to keep hands, living environment and desk clean in daily life and work.For importers,it is necessary to tell consumers on the packaging of products about the use of sanitizer and precautions,otherwise it will easily endanger consumers’ personal safety and even cause fire. This is actually the key point involved in packaging quality control. It can be seen that the information on the packaging is the first one that consumers come into contact with.Especially for sanitizer,it will cause danger once it is used incorrectly,which needs to be clearly marked.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.