What is the Difference Between Different Grades of Stainless Steel? How To Test Them?

By Daniel Tsui • 07/3 @ 6:55 • What is the Difference Between Different Grades of Stainless Steel? How To Test Them?已关闭评论

What kind of steel is stainless steel?

Stainless steel is a kind of steel, which contains less than 2 % carbon ( C )is called steel, while more than 2 % is iron. The addition of chromium ( Cr ), nickel ( Ni ), manganese ( Mn ), silicon ( Si ), titanium ( Ti ), molybdenum ( Mo ) and other alloying elements in the steel during smelting, improves the performance of the steel and gives the steel corrosion resistance, which is what we often call stainless steel. So what are the key points of Stainless steel quality control to pay attention to? First, we need to know how stainless steel is classified.

Why does stainless steel have different steel grades?

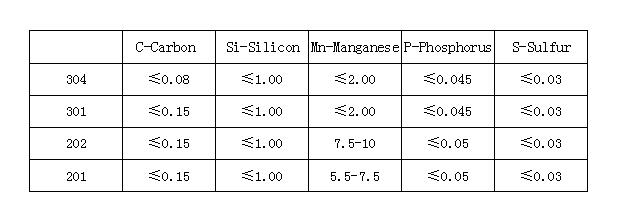

In the process of stainless steel smelting, according to different requirements, different kinds of alloying elements are added and different amounts of alloying elements are added, so the characteristics of the finished products will be definitely different. In order to distinguish them, different steel grades are put on the table. Here are the ” alloying elements” contents of different steel grades of common stainless steel for reference only: chemical composition ( mass fraction, % )

What kind of stainless steel does not rust easily?

There are three main factors affecting stainless steel corrosion:

1.The content of alloying elements.

The higher the chromium and nickel content, the better the corrosion resistance. Normally, steel containing more than 10.5 % chromium is not easy to rust.

Such as 304 material, nickel content is 8 – 10% and chromium content is 18 – 20 %. Such stainless steel will not rust under normal circumstances.

2.The smelting process of the production enterprise and the stainless steel quality control standard also affect the corrosion resistance of stainless steel.

The stainless steel factory with good smelting technology, advanced equipment, advanced technology and perfect stainless steel quality control management can be guaranteed both in the control of alloying elements, impurity removal and billet cooling temperature, and the product quality is stable and reliable, with good internal quality and is not easy to rust. On the contrary, some small steel mills are backward in equipment and technology, without a perfect stainless steel quality control system or even quality control procedures, impurities cannot be removed during smelting, and the products produced will inevitably rust.

3.External environment.

The dry and ventilated environment in the climate is not easy to rust, while the environment with high humidity and continuous rainy weather or high PH value in the air is easy to rust. Even 304 stainless steel will rust if the surrounding environment is too bad.

What kind of inspection does stainless steel generally have to carry out?

Generally speaking, the test of stainless steel quality control is divided into two items: chemical composition ( content of carbon, silicon, phosphorus, sulfur, chromium, manganese, nickel, etc. ) and physical properties ( yield strength, tensile strength, hardness, elongation, etc. ).

In the export trade, many international buyers have chosen to employ a third-party inspection agency for stainless steel quality control.

The main tasks are:

- Confirm whether the chemical composition and performance of the batch of stainless steel meet the requirements;

- Check and confirm the order quantity, weight and other parameters;

- Loading inspection.

As for stainless steel quality control, both chemical and physical tests need to be carried out by instruments in the laboratory. Importers who are cautious will require a third-party inspector to go to the site. If the factory has a laboratory, they can randomly take samples for testing, or the importers will require a third-party inspector to randomly take samples from mass production and send them directly to a third-party laboratory for analysis and testing. Why do you want random sampling on site and how do you take samples, please refer to Avoid Fake Testing Samples and Random Sample picking These two articles.

Other people will think that when inspecting stainless steel, they use small magnets to suck products, and think that the quality is good due to it can’t be sucked, because they won’t rust without magnetism. CLI Inspection Company believes this is a completely wrong understanding of stainless steel quality control.

In fact, the non-magnetic nature of the stainless steel strip is determined by the structure. Stainless steel with different structures such as ” ferrite”, ” austenite” and ” martensite” will be formed due to the different solidification temperatures during the solidification process of molten steel, among which ” ferrite” and ” martensite” stainless steel contain magnetism. However, although ” austenitic” stainless steel is not magnetic and its comprehensive mechanical properties, technological properties and weldability are good, it is better than ” austenitic” stainless steel only in terms of corrosion resistance.

At present, the high manganese content and low nickel content in the market circulation, the so-called 200 series and 300 series stainless steel also do not contain magnetism, but its performance is far from that of 304 stainless steel with high nickel content. On the contrary, 304 will also be slightly magnetized after stretching, annealing, polishing, casting and other processes. Therefore, it is a misunderstanding and unscientific to judge whether stainless steel has magnetism or not.

Therefore, in the steel export trade, professional third-party service for stainless steel quality control can effectively find out the quality problems existing in the products before delivery, so as to let customers know in advance, protect their supply chain security , avoid or reduce losses. This is Advantages of outsourcing inspection.

This article is an original article for CLI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CLI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CLI Inspection, thank you.

Daniel Tsui

Senior professionals in the field of quality inspection are committed to finding and sharing valuable experiences.

SEARCH

Email Subscribers

Recent Posts

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45

- Are You Still Worried About Clothes Damaged by Hangers? 03/29 @ 8:26

Recent Comments

Monthly Files

Catalogue

Tags

BLOG

- register-081823 08/18 @ 8:03

- A Few Tricks to Teach You How to Easily Buy Luggage Case Bags With High Cost Performance ? 04/20 @ 8:47

- You Can’t Imagine That A Big Brand Like KAPPA Will Find Serious Batch Problems During Inspection! 04/13 @ 9:08

- Folding Table: Technological Comparison Between Two Factories 04/6 @ 8:45